Table of Contents

1.A.2.a - Stationary Combustion in Manufacturing Industries and Construction: Iron and Steel

Short description

| Category Code | Method | AD | EF | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.A.2.a | T2 | NS | ? | ||||||||||||

| Key Category | SO₂ | NOₓ | NH₃ | NMVOC | CO | BC | Pb | Hg | Cd | Diox | PAH | HCB | TSP | PM₁₀ | PM₂ ₅ |

| 1.A.2.a | -/- | -/T | -/- | -/- | -/- | - | - | -/- | - | -/- | -/- | - | -/- | -/- | -/- |

In 2019, a total of 27.7 million t of raw steel was produced in six integrated steelworks. Electrical steel production amounted to another 11.9 million t.

The structural elements of this category are the production of pig iron (blast furnaces), sponge iron (direct reduction), sinter, rolled steel, iron and steel casting, Siemens-Martin steel (in the new German Länder only until shortly after 1990), electric steel and the power stations and boilers of the entire steel production.

In category 1.A.2.a Iron and Steel only emissions of

- CO (for all years exept 2008-2010, where only CO emissions from ferrous metal foundries are reported),

- NH3 (until 1999 and then for the years 2010 and later; from 2000 to 2009 only NH3 emissions from use of coal and coke in electric steelworks are reported),

- NMVOC and NOx (until 1999),

- PM2.5, PM10 and TSP (until 2007 and then for the years 2010 and later; for 2008 and 2009 only emissions from the use of fuel gases sinter plants (ignition hoods) are reported) and

- SO2 (untiil 1999; SO2 emissions from the use of coal and coke in electric steelworks until 2000 and in 2004)

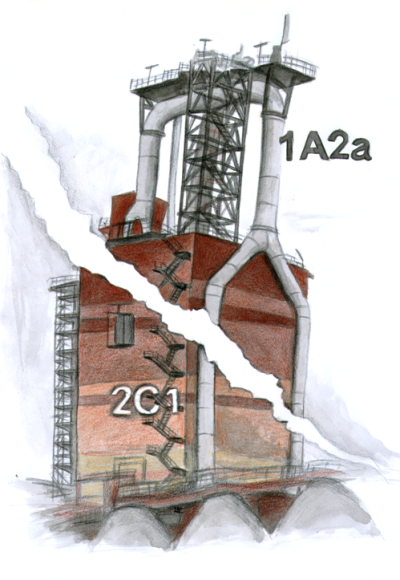

are reported. The emissions of these pollutants in other years as well as emissions of other pollutants are reported under Category 2.C.1 (see explanation below).

Category 1.A.2.a Iron and Steel is a trend key category for NOx (mainly because the NOx emissions reported here until 1999 are then reported under Category 2.C.1).

Methods

Activity data

Data source of the fuel consumption for iron and steel casting is the statistic for the manufacturing sector; Statistik 060 - Energieverwendung des produzierenden Gewerbes (Energy use in the manufacturing sector; DESTATIS), reporting-numbers 27.21, 27.51 and 27.52. Fuel consumption data for the hot metal production as well as the production of sinter and hot rolling are collected by the steel trade association (WV Stahl) in continuation of the former National Statistic: Fachserie 4, Reihe 8.1.

Emission factors

The emission factors used for the years 1990 - 1994 were taken from the report on the research project “Ermittlung und Evaluierung von Emissionsfaktoren für Feuerungsanlagen in Deutschland für die Jahre 1995, 2000 und 2010” (Determination and evaluation of emission factors for combustion systems in Germany for the years 1995, 2000 and 2010“; RENTZ et al, 2002)1). Starting from 1995 new emission factors for iron and steel were determined, based on real emission data from the installations concerned. (1995-2001: own calculations by UBA; EF for 2008 by a research project by the steel industry´s research institut BSI.

In category 1.A.2.a - Iron and Steel only emissions from power plants and steam boiler of the steel industry are reported. Basically, all industrial power plants and steam boiler are reported in source category 1.A.2.gviii - Other since the emission behaviour is comparable. The reason for the different structure of 1.A.2.a are the requirements of the UNFCCC Guidelines and the resulting review proceedings. Insofar it is more sensible to report all emissions from blast furnace fired power plants and steam boiler in Source category 1.A.2.a to avoid notes regarding CO2 IEFs.

Whereever emission factors were determined from real emission data of the installations concerned, both process and energy related emissions from the production of sinter, pig iron (blast furnace including the cowpers), steel (both BOF and EAF steel production), rolled steel as well as from cast iron and steel are reported under Category 2.C.1, since it is not possible to separate combustion from process emissions within the same stack. Insofar in later years the emissions of the most pollutants are reported under 2.C.1.

Trend discussion for Key Sources

NFR 1.A.2.a - Iron and Steel is key source by trend for NOx.

Recalculations

Recalculations were necessary for the latest reference year due to the availability of the National Energy Balance. Germany's federal structure causes a time lag for the National Energy Balance. Therefore recalculations are always necessary.

For more information on recalculated emission estimates for Base Year and 2018, please see the pollutant specific recalculation tables following chapter 8.1 - Recalculations.

Planned improvements

At the moment, no category-specific improvements are planned.