Table of Contents

1.A.1.b - Petroleum Refining

Short description

Source catagory Petroleum Refining (1.A.1.b) comprises both refinery heating plants and electricity and heat production of refinery power plants.

| Category Code | Method | AD | EF | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.A.1.b | T2 | NS | CS | ||||||||||||

| NOx | NMVOC | SO2 | NH3 | PM2.5 | PM10 | TSP | BC | CO | PB | Cd | Hg | Diox | PAH | HCB | |

| Key Category: | -/- | -/- | L/- | -/- | -/- | -/- | -/- | -/- | -/- | -/- | L/- | -/- | -/- | -/- | - |

Methodology

Refinery processes are very complex. Therefore the development of an adequate calculation method is demanding. Since plant specific data are not complete and partly contradictory, a plant specific reporting is not possible. Data is used to determine fuel specific emission factors as general basis of the calculation model. However, in reality, a large number of several fuels and waste fuels with different fuel characteristics is used for combustion processes. Insofar the calculation model is limited. Only some refinery power plants use wet desulfurisation in order to decrease sulfur emissions. Usually the fuels mix ensures the compliance with the limit values.

Activity data

Fuel inputs for electricity production in refinery power stations are included in Energy Balance line 12 (“Industrial thermal power stations”). Energy Balance line 38 shows energy consumption (for heat production) of refineries (AGEB 2019)1).

Fuel inputs for heat production in refinery power plants and for bottom heating in refinery processes, are derived from these figures. Activity rates for refineries for fuel inputs for electricity and heat production in petroleum refining are determined by combining the national statistics of the Federal statistical Office (DESTATIS) and the Federal Office of Economics and Export Control (BAFA).

Energy inputs in facilities for used-oil processing are reported under 1.A.1.c - Manufacture Of Solid Fuels And Other Energy Industries sector.

Emission factors

The emission factors for refinery power plants have been taken from the research project “Determination and evaluation of emission factors for combustion systems in Germany for the years 1995, 2000 and 2010” (Rentz et al 2002)2). A detailed description of the procedure is presented in Chapter: 1.A.1.a - Public Electricity And Heat Production.

Emission factors are available for different fuel types and combustion technologies. The distinction between refinery power plants and bottom heating in refinery processes is necessary since bottom heating systems have considerably higher specific emissions. A running project which has to evaluate data from emission declarations for the years 2004, 2008, 2012 and 2016 for all refineries will provide refinery gas emission factor data for Submission 2020. The first results show the following range:

Table 1: Range of emission factors, in kg/TJ

| Range | |

|---|---|

| SO2 | 4.79 - 16.09 |

| CO | 1.02 - 1.85 |

| NOX | 36.71 - 45.60 |

| NMVOC | 0.843 - 1.170 |

| TSP | 0.24 - 0.37 |

Before the new emission factors can be used, it has to be checked which data are representative. Further quality checks are necessary in order to reproduce the trend correctly.

Trend discussion for Key Sources

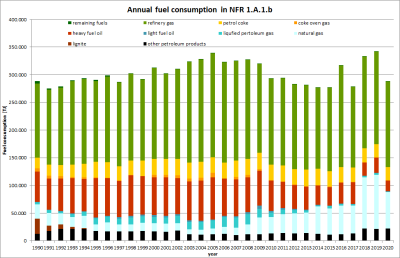

The following diagram gives an overview of the fuel consumption in the refinery sector.

Since 1990, fuel consumption has shown a slightly increasing trend overall. While some relevant installations have been decommissioned since 1990 - especially in the territory of the former GDR - production increased nevertheless. And while installation efficiencies were improved, increased production of lighter petroleum products and intensified hydrosulphurisation, which led to increases in specific fuel consumptions. Annual fluctuations of all fuel types can be explained as the result of differences in production quantities. The maximum production of petroleum products to date, totalling 123.6 million t, occurred in 2005, as a result of a shortfall in capacity in the USA, which led to an increase in imports. Thereafter, production decreased by reducing excess capacities like everywhere in Europe. The increasing use of natural gas in recent years led to decreasing emissions of all emissions (except NOx ).

Recalculations

Recalculations were necessary for 2019 due to the implementation of the now finalised National Energy Balance.

For pollutant-specific information on recalculated emission estimates for Base Year and 2019, please see the recalculation tables following chapter 8.1 - Recalculations.

Planned improvements

It is planned to revise emission factors for all pollutants on the basis of the above mentioned project.