meta data for this page

1.A.2.g viii - Stationary Combustion in Manufacturing Industries and Construction: Other

Short description

Source category 1.A.2.g viii - Stationary Combustion in Manufacturing Industries and Construction: Other comprises stationary combustion systems for heat and power production of industrial power plants and industrial boiler systems.

| Category Code | Method | AD | EF | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.A.2.g viii | T2 | NS | CS | ||||||||||||

| Key Category | SO₂ | NOₓ | NH₃ | NMVOC | CO | BC | Pb | Hg | Cd | Diox | PAH | HCB | TSP | PM₁₀ | PM₂ ₅ |

| 1.A.2.g viii | L/T | L/T | -/- | -/- | -/- | -/- | -/- | L/T | L/T | L/T | -/- | -/- | L/T | -/- | L/- |

Method

Generally, the calculation method is based on a Tier 2 approach. This means the use of country-specific data at a more detailed level. Emission factors and activity data are available for different fuel types, different technologies, plant size, etc. The use of plant-specific data for a bottom-up approach is not possible. Emissions from industrial power plants cannot be allocated clearly to source category 1.A.2, since reality does not follow the definition of the Guidebook. In real life an industrial power plant generates electricity and heat for the industry but also electricity for the public network. Therefore the borderline between these two categories is not fixed. The market is not static. Frequent changes in the cooperate structure of industrial enterprises including the separation of the energy supply via spin-off from the parent company lead to frequent changes between sector 1.A.1.a, 1.A.1.c and 1.A.2. Therefore it was necessary to develop a flexible calculation system, based on robust emission factors, which can be used for all sectors. Source category 1.A.2.g.viii does only include emissions from industrial power plants and boiler systems.

Activity data

Conventional fuels

The key source of all conventional fuel data is the national energy balance (AGEB, 2019)1). Moreover the use of additional statistical data is necessary in order to disaggregate data. Data source for fuel inputs for electricity generation in industrial power stations are shown in Energy Balance line 12. The difference resulting after deduction of the fuel inputs for refinery power stations, pit power stations, power stations in the hard-coal-mining sector and, for the period until 1999, for the power stations of German Railways (Deutsche Bahn) consists of the activity data for other industrial power stations. These data cannot be further differentiated. Additional data from the Federal Statistical Office are needed for allocation of fuel inputs to heat production in industrial power stations and boiler systems. For both electricity production and heat production, gas turbines, gas and steam systems and gas engines are differentiated. These detailed information is provided by the national statistic 067 (industrial power stations). The definition of industrial and public power plants follows the National statistics.

Biomass

Along with the main Energy Balance, a Satellite Balance of renewable Energies (Satellitenbilanz Erneuerbarer Energieträger) is also published. This balance describes the growth and use of renewable energies in detail. This is the database for all biomass fuels excluding waste.

Waste

With regard to determination of activity data from waste incineration and co-combustion of waste in combustion system in source category 1.A.2 Energy Balance and energy statistics show smaller waste quantities than the waste statistics of the Federal Statistical Office (Statistisches Bundesamt, Fachserie 19, Reihe 1) 2). For that reason activity data were taken from waste statistics.

Emission factors

The emission factors for power stations and other boiler combustion for production of steam and hot water, in source category 1.A.2.g.viii, have been taken from the research project “Determination and evaluation of emission factors for combustion systems in Germany for the years 1995, 2000 and 2010” (RENTZ et al., 2002)3). In 2018 and 2019 SO2, NOx, TSP, PM, CO, NH3 and Hg emission factors were revised for all large combustion plants by using data from the large combustion plant reporting (UBA 2019)4). A detailed description of the procedure is presented in Chapter: 1.A.1.a - Public Electricity And Heat Production. This chapter contains also information about emission factors of engines and waste incineration plants. In terms of black carbon default emission factors for the EMEP EEA Guidebook 2016 where used.

Table 1: Implied emission factors for industrial electricity and heat generation

| SOx | NOx | TSP | CO | Pb | Hg | Cd | |

|---|---|---|---|---|---|---|---|

| [kg/TJ] | [g/TJ] | ||||||

| Hard Coal | 142.9 | 101.3 | 3.3 | 26.0 | 4.94 | 2.35 | 0.36 |

| Lignite | 221.9 | 98.1 | 7.4 | 47.5 | 1.15 | 2.42 | 0.15 |

| Natural gas | 0.1 | 41.4 | 0.2 | 11.0 | NA | 0.01 | NA |

| Petroleum products | 55.4 | 49.2 | 1.8 | 3.3 | 0.79 | 0.18 | 0.03 |

| Biomass | 10.1 | 136.9 | 18.5 | 56.2 | 0.44 | 0.11 | 0.55 |

| Hazardous Waste | 0.5 | 69.2 | 0.3 | 8.3 | 4.90 | 0.34 | 1.10 |

The table gives an overview of the implied emission factors. In reality the German inventory compiling process is very complex and includes the use of a considerable number of emission factors, which cannot be published completely in the IIR.

Actually there are different emission factors available for diverse fuel types, various techniques and licensing requirements. However, the implied emission factor may give an impression about the order of magnitude. PM10 and PM2.5 emission factors are calculated as a fraction of TSP. The share of PM10 is 90 % and the share of PM2.5 is 80 % for solid fuels. This is a simple but also conservative approach, knowing that, in reality, PM emissions depend on fuel, combustion and abatement technologies. In terms of natural gas and biogas PM10 and PM2.5 fractions are considered as 100 % of TSP. Regarding wood a share of 100% PM10 and 90% PM2.5 is used. For liquid fuels the default share of 100% PM10 and PM2.5 is used. In the cases of co-incineration, where liquid fuels are only used for ignition in coal fired plants, the share of coal fired plants is used. PM emission reporting starts in 1995, since no sufficient information about the dust composition of the early 1990s is available.

Trend Discussion for Key Sources

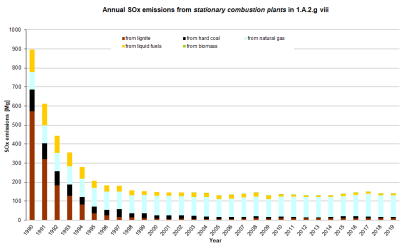

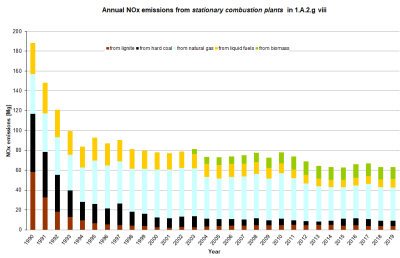

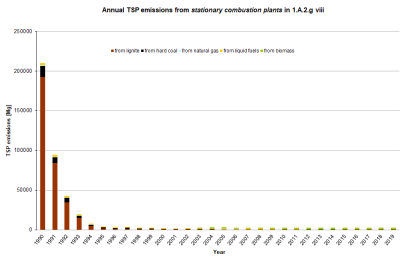

The following diagrams give an overview and assistance for explaining dominant emission trends of selected pollutant.

Sulfur Oxides & Nitrogen Oxides - SOx & NOx

Like already discussed in source category 1.A.1.c, SOx emission trend is very much influenced by emissions from lignite fired plants. The strong decline of lignite use in the East German industry and the installation of flue gas desulfurisation plants in the remaining heat and power stations are the main reasons for decreasing SOx emissions.

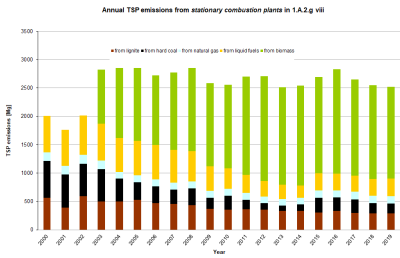

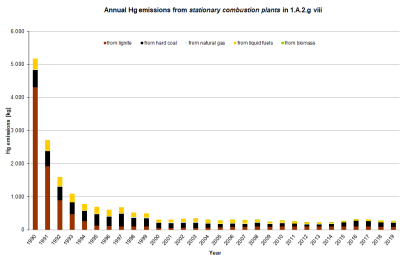

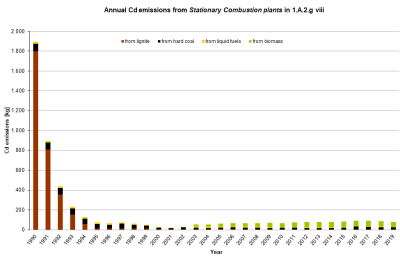

Total Suspended Matter - TSP & Priority Heavy Metal - Hg & Cd

The main driver of TSP and Heavy Metal emission trends is the declining lignite combustion in the East German industry especially in the time period from 1990 to 1994. Besides the noticeable improvement of dust extraction installations on the one hand and optimisation of the combustion process on the other hand resulted in considerably decreasing TSP and Heavy Metal emissions. The emission trend of source category 1.A2.g.viii is mainly affected by the closure of industrial plants in Eastern Germany after the reunification and the resulting decrease in fuel consumption. In recent years the use of biomass gains influence.

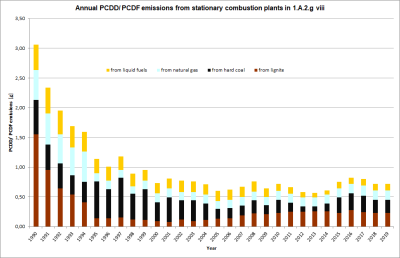

Persistent Organic Pollutants

PCDD and PCDF emissions show a falling trend over the whole time period due to decreasing fuel consumption in the industry sector.

Recalculations

Recalculations were necessary for the latest reference year (2018) due to the availability of the National Energy Balance. Germany has a federal structure which causes a time lag for the National Energy Balance. Therefore recalculations are always necessary.

For pollutant-specific information on recalculated emission estimates reported for Base Year and 2018, please see the pollutant specific recalculation tables following chapter 8.1 - Recalculations.

Planned improvements

Currently no improvements are planned.